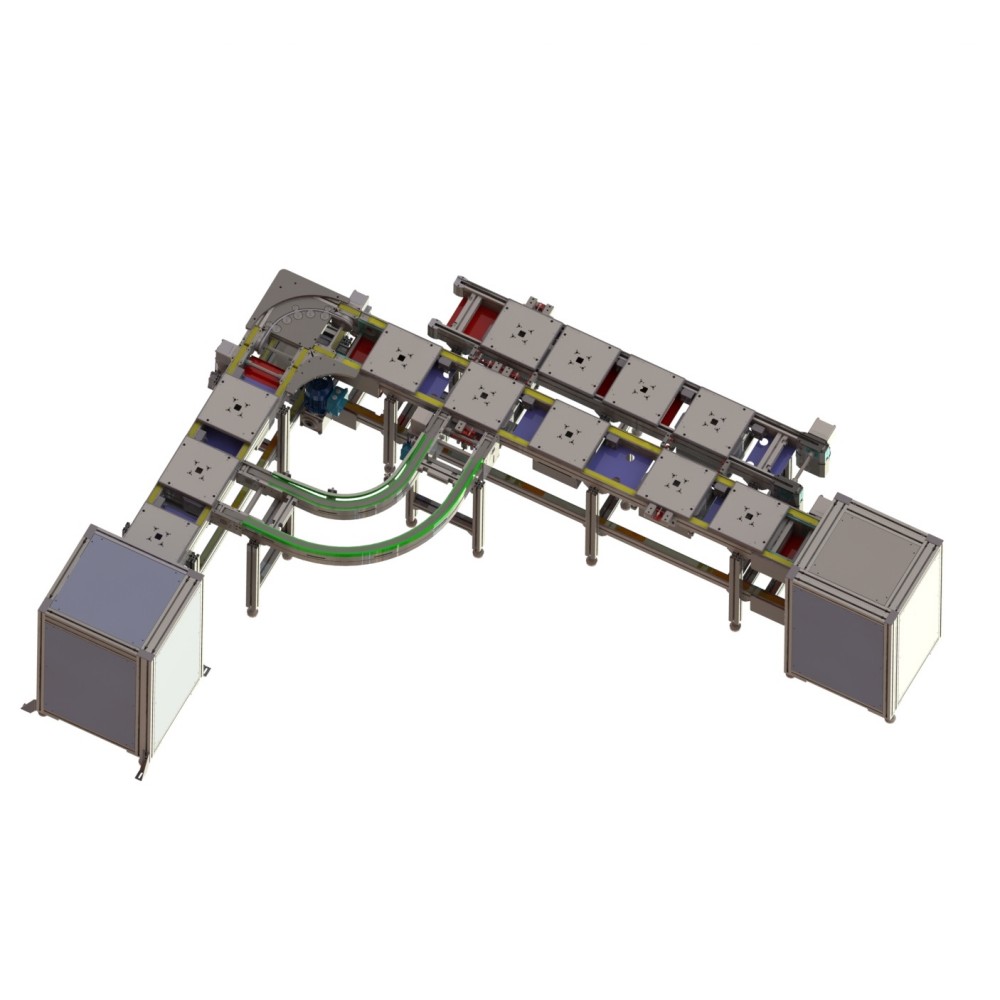

In the realm of automated material handling, Pallet Transfer Systems emerge as champions, offering a myriad of advantages that redefine efficiency in production lines. These 12 key benefits showcase why businesses are increasingly turning to these innovative Conveyor systems for their material handling needs.

1. Automated Precision:Conveyor Positioning: Pallet transfer systems excel in automated precision, ensuring accurate positioning for seamless production processes. The incorporation of advanced motor control and rotation features optimizes material flow.

2. Versatile Handling:Tray conveyor: From trays to batteries, these systems handle a diverse range of materials with ease, making them versatile solutions for a variety of industries, from electronics assembly to automotive manufacturing.

3. Modular Design:Scalability: Pallet transfer systems feature a modular design, allowing for easy scalability. Businesses can expand their operations effortlessly by adding or modifying conveyor segments to meet evolving production demands.

4. Efficient Curve Navigation:Conveyor Curve: The ability to navigate curves efficiently ensures a smooth flow of materials through the production line, eliminating bottlenecks and enhancing overall system efficiency.

5. Space Optimization:Compact Design: Designed with a compact footprint, these conveyors optimize floor space utilization, making them ideal for facilities with space constraints. The modular design further enhances space optimization.

6. Tailored Designs:Custom Solutions: Pallet transfer systems come with various designs, including flat belts, plastic chains, and Roller chains. This customization allows manufacturers to tailor the system to their specific production needs.

7. Energy Efficiency:Advanced Motor Control: These systems prioritize energy efficiency, incorporating advanced motor control technologies to minimize energy consumption. This not only reduces operational costs but also aligns with sustainable manufacturing practices.

8. Sustainable Materials:Environmentally Friendly: Manufacturers, like Vitrans, focus on sustainability by using recyclable materials in the construction of their conveyor systems. This commitment to environmental responsibility ensures a reduced ecological impact.

9. Smooth Transitions:Production Line Integration: Pallet transfer systems facilitate seamless transitions between different stages of production, enhancing overall workflow efficiency in assembly line settings.

10. Pallet System Compatibility: – Pallet System: These conveyors are specifically designed for compatibility with pallet systems, offering a comprehensive solution for businesses involved in Pallet Handling.

11. Reliable Stoppage Control: – Conveyor Stopper: With advanced stopper mechanisms, these systems provide reliable control over stoppage points, preventing collisions and ensuring safe and efficient material handling.

12. Precision Handling Solutions: – Pallet Handling Solutions: Whether it’s tray handling or battery conveyance, these systems provide precision handling solutions that are crucial for maintaining product quality and production accuracy.

In conclusion, Pallet Transfer Systems epitomize the future of automated material handling, offering a blend of precision, versatility, and sustainability. As industries evolve, these systems stand as pillars of efficiency, providing businesses with the competitive edge needed in the modern manufacturing landscape.”