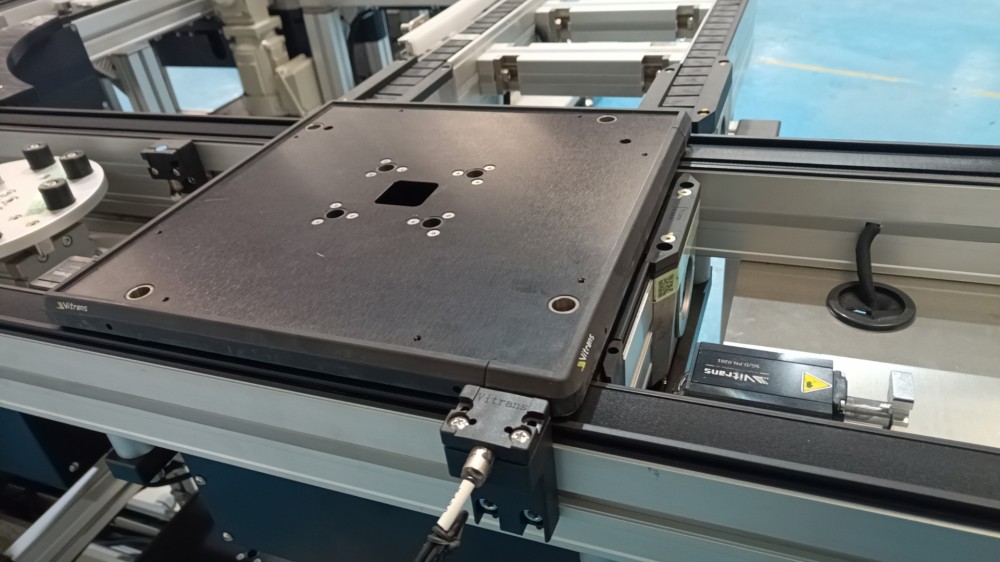

Palettenförderer, eine fortschrittliche Form der Automatisiertes Förderband Systeme gestalten die Landschaft der industriellen Automatisierung neu. Im Gegensatz zu herkömmlichen Förderern bieten Palettenförderer ein modulares und vielseitiges Design, das auf die spezifischen Bedürfnisse verschiedener Branchen zugeschnitten ist. Von Montagelinien bis zu Fabrikhallen spielen diese Förderer eine zentrale Rolle bei der Rationalisierung von Produktionsprozessen.

Hauptmerkmale und Vorteile:

Modularer Aufbau: Die Palettenförderer sind modular aufgebaut und gewährleisten eine einfache Installation und Wartung.

Flexibilität: Ihr flexibles Design ermöglicht nahtlose Upgrades und Modifikationen und passt sich so den sich ändernden Produktionsanforderungen an.

Lastvielfalt: Maßgeschneidert für unterschiedliche Tragfähigkeiten, mit Optionen wie Gurtförderern für leichte Lasten, Kettenförderern für mittlere Lasten und Walze Förderer für schwere Lasten.

Größe Anpassungsfähigkeit: Die Palettenförderer eignen sich für eine Reihe von Produktgrößen und unterstützen Paletten von 160 mm bis 1200 mm.

Akkumulationsfähigkeit: Ermöglicht die Stapelung von Paletten, was die Gesamteffizienz der Produktion erhöht.

Präzise Positionierung: Präzise Produktpositionierung mit Positioniereinheiten, die den Anforderungen automatisierter Abläufe gerecht werden.

Automatisierte Richtungsänderungen: Ermöglicht automatische Änderungen der Produktausrichtung zur Erfüllung der Produktionsanforderungen.

ESD-Konformität: Erfüllung der ESD-Normen (Electrostatic Discharge) für erhöhte Produktsicherheit.

Low Staub und Lärm: Ideal für Reinraumumgebungen mit geringem Staubaufkommen und niedrigem Geräuschpegel.

Gepuffertes Design: Mit einem Pufferdesign, das Stöße während des Produktflusses in der Produktionslinie verhindert.

Vitrans, ein führender Hersteller, hebt sich auf dem Markt durch seine Paletten-Fördersystemeund bietet einen Wettbewerbsvorteil in Bezug auf Preis und Qualität im Vergleich zu Konkurrenten wie Bosch, Dorner und Flexlink. Verbessern Sie Ihre Fertigungsprozesse mit der Effizienz und Präzision der Palettenförderer von Vitrans."