Pallet Conveyor and conventional Conveyor exhibit distinctions in terms of design, purpose, and application scenarios. Here are some key differences:

(Conventional conveyor)

Purpose and Application:

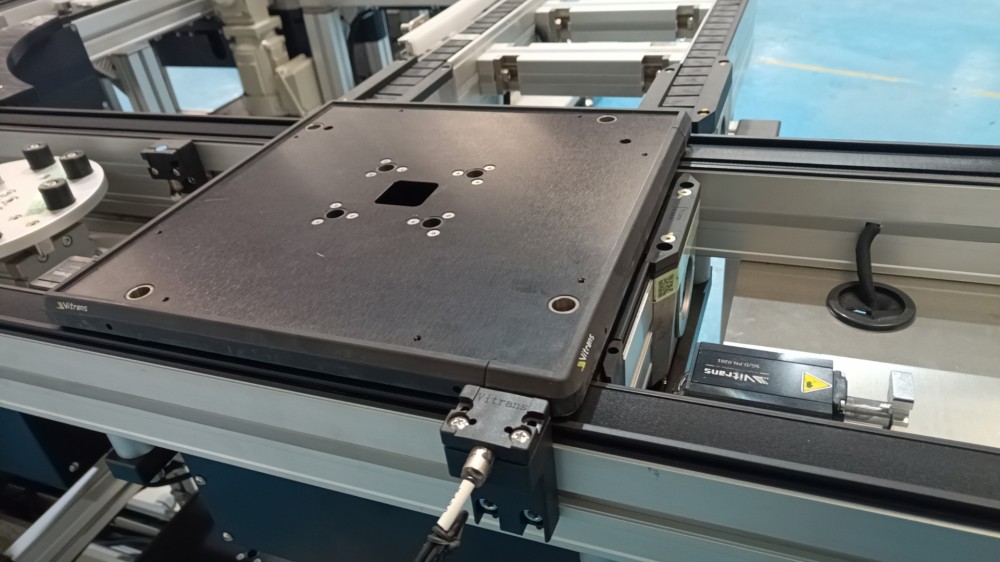

Pallet Conveyor: Primarily utilized for transporting, positioning, and assembling pallets or similar carriers. Ideal for processes requiring specific arrangements and combinations, such as assembly lines or production lines.

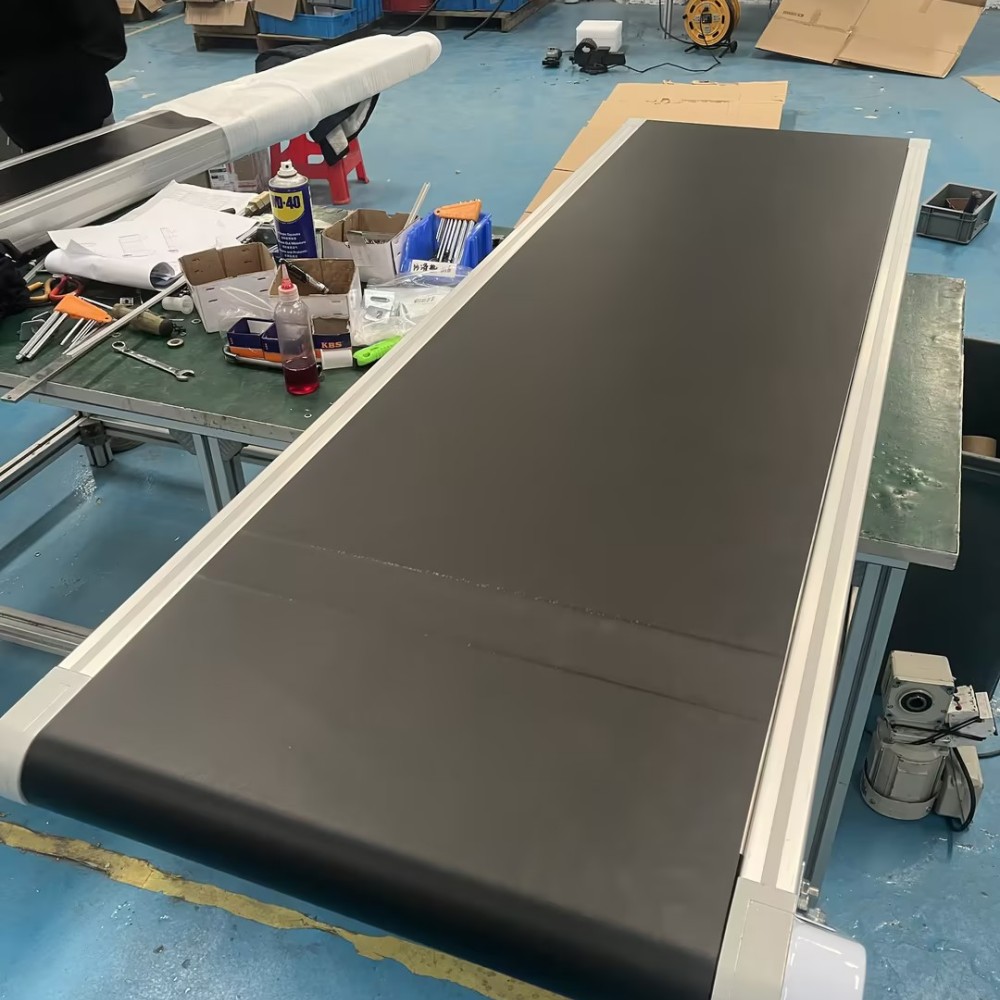

Conventional Conveyor: More versatile, designed for transporting various types and shapes of items, including boxes, packages, parts, etc. Suited for the transportation of items without the need for special arrangements.

Design and Structure:

Pallet Conveyor: Typically designed to fix and precisely control the movement of pallets. May include positioning and directional technologies to ensure accurate product arrangement.

Conventional Conveyor: Relatively simple in structure, intended for conveying objects of various shapes and sizes, without necessarily involving special positioning and arrangement requirements.

Applicable Types of Products:

Pallet Conveyor: Specialized for conveying pallets, containers, or carriers. Suitable for large, heavy, or products requiring specific arrangements.

Conventional Conveyor: Applicable to various product types, whether small parts, packaging boxes, or larger items.

Production Line Flexibility:

Pallet Conveyor: Typically more flexible, suitable for environments requiring frequent changes in product arrangement or production line configurations.

Conventional Conveyor: Less flexible when dealing with various products, more suitable for relatively fixed production line configurations.

Automation Level:

Pallet Conveyor: Often used in highly automated production lines, equipped with advanced control and positioning technology.

Conventional Conveyor: Applicable across a range of automation levels, from manual operations to highly automated production lines.

In summary, Pallet Conveyor is more specialized for the handling and arrangement of specific types of products, such as pallets, while Conventional Conveyor is more versatile, accommodating the transportation of various objects. The choice between the two depends on the specific requirements of the production line and the characteristics of the products being handled.